The improvement direction of small bag packing machine

Because small packaged food is convenient to carry, it satisfies people’s appetite to enjoy the original taste and is convenient to share with others. It has become the first choice of young consumer groups, especially young women, and some business travelers also like these foods. Small packaged food is popular among these online shoppers because of its simplicity, convenience, safety and hygiene, and small packaged food such as dried fruits, dried beans, seafood and meat has become the most popular leisure food. In addition, many businesses also play “healthy, balanced nutrition” and other slogans, launched small packages of multi-grain biscuits, VC and other nutritional products, are also deeply loved by the elderly. Small packaged snacks hot promote the small bag packaging equipment in the market position.

In many countries, the main characteristics of bag-making and filling packaging machine: In recent years, the development of foreign bag-making and filling packaging machine is characterized by the production trend of more standardized, special, convenient. Computer technology is widely used in the automatic control of the production process, and equipped with a variety of parameter measurement devices, so that packaging, measurement, bagging, sealing and cutting, printing, testing machine to complete. To ensure the quality of packaging, to achieve high efficiency, low cost requirements.

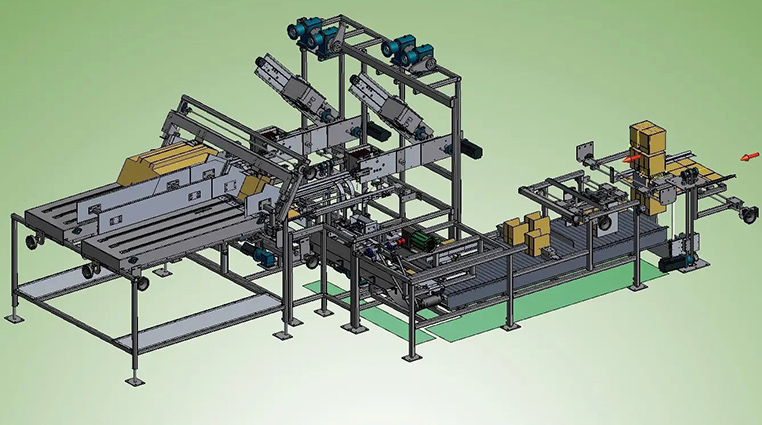

In order to meet the requirements of modern product diversification, the small bag packaging machine is constantly developing to adapt to the variety of small batch general packaging machinery and equipment, so that the form of packaging machinery is increasing. Bag making and filling packing machine is a kind of automatic packing equipment that can automatically complete the whole process of bag making, metering and filling, sealing and cutting, etc. by heating and softening the plastic composite film with thermoplastic characteristics into packaging containers. For example, ketchup, small bags of milk powder, instant noodles seasoning and other small bag packaging equipment. Too many food products today have changed from massive manual packaging to quantitative small packaging. This is because when calculating the cost of the whole system, the net profit of small packaging products is higher than that of large packaging products, because the waste and loss will be greatly reduced.

Therefore, on the premise of user demand, we provide users with structural and economical complete system solutions.

With the continuous development of packaging machinery, it is difficult for users to fully understand the structural characteristics of products, performance indicators and adapt to the environment, which requires enterprises to do a good job of technical advice and support users, not only can answer the questions raised by users accurately and in detail, but also can provide rapid and accurate after-sales service, and establish a long-term partnership with users.