Automatic Small Conveyor Belt Granule Packing Machine

Automatic Small Conveyor Belt Granule Packing MachineType: Nuts, candies, sea salt, monosodium glutamate, soybeans, candies, granular medicines, seeds, crushed peanuts, puffed food, gummies, biscuits, melon seeds, cereal porridge, jelly and other granular items

Scope of application: Widely used in prefabricated bag packaging of granular, block and sheet materials in food, medicine, daily chemical and other industries.

Type: Nuts, candies, sea salt, monosodium glutamate, soybeans, candies, granular medicines, seeds, crushed peanuts, puffed food, gummies, biscuits, melon seeds, cereal porridge, jelly and other granular items

Performance characteristics:

- The whole machine adopts full servo control system, the machine runs smoothly, the action is precise, the performance is stable, the packaging efficiency is high, and the maintenance is convenient;

- The equipment accessories adopt domestic/international famous brand electrical components, and after years of market practice tests, to ensure more stable and durable performance;

- Made of stainless steel sheet metal processing and assembly, the operation is stable; and the core components are specially optimized for fast packaging;

- The weighing system of the combined scale is selected from a well-known brand manufacturer, with stable performance and high efficiency;

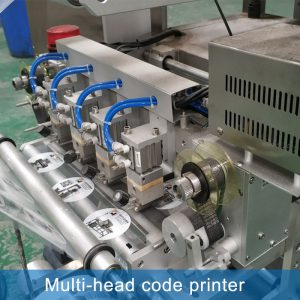

- Various coding, inkjet, exhaust and punching systems are optional;

Composition accessories: host + particle combination scale + platform + Z-shaped hoist

Technical Features:

- According to the structure of the packaging host, we can design a combination of micro combination scales and packaging hosts to form an all-in-one machine, saving space and cost for customers.

- The duckbill-shaped servo collecting hopper can concentrate the material to one point for filling to meet the high speed requirement.

- The display interface can be customized according to the needs.

- Weighing detection and photoelectric eye detection are shared to meet the requirements of different material characteristics.

- Automatically adjust the line amplitude to achieve the best accuracy in the process of automatic weighing of materials.

- The original preset parameter formula makes the operation easier, and the formula can be saved with any choice of path, name and pattern.

- The material stopper moves up and down to reduce the collision of materials, especially suitable for fragile products.

| Device model | MD-180K | ||

| production efficiency | 15-40 bags/min ( customizable ) | ||

| Package weight | 1-1000g ( customizable ) | ||

| Packaging error | ±0.2g-3.0g ( customizable ) | ||

| Control System | Servo controller + color touch screen | ||

| bag width | 80mm — 1810mm _ | ||

| bag length | 110mm-320mm | ||

| Bag type | Stand-up bags, four-side seal bags, zipper bags, handbags, paper bags and other prefabricated bags | ||

| Applicable packaging material | PP, PE, PVC, PS, EVA, PET, PVDC+PVC, OPP+composite CPP, etc. | ||

| Equipment material | Stainless steel (carbon steel) rack | ||

| Device power | 380V /50Hz/ 3.2KW | Air consumption | 0.6m3/min |

| Machine size (LWH) | 3600*1800*3750mm | machine weight | 1200kg |

| Packaging machine optional device | Zipper opening device,Exhaust,coding machine,Inkjet printer,Shaped die cutting | ||

Reviews

There are no reviews yet.